Water Jet cutting is characterized by high accuracy and versality of its application, which allow for the device to be used for processing of the following materials:

- Flat glass

- Multilayer glass laminated with film or resin

- Armoured glass

- Mirrors

- Stainless steel

- Copper

- Aluminum

- Waterproof plywood

- Brass

- Plastic

- Acrylic, polycarbonate

- Cork

- Foam

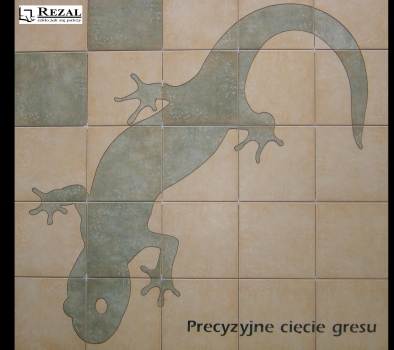

- Ceramic materials

- Glazed tiles, terracotta, stoneware, porcelain

- Natural stone

- Marble, Granite, Sandstone

- Artificial stone

- Rubber

- Foil

- Leather

- Wood

- And many other materials

We offer water cutting packet, for example, 6 sheets of steel with a thickness of 1.5 mm.

Water Jet cutting is done based on drawings, sketches, CAD designs, templates, photos.

We offer:

- Cold shape cutting, ensuring no changes in the material structures, no microcracks, and no local hardening or internal stress.

- Maximum glass dimensions: 3000 x 1500 mm

- Thickness of the material for water cutting: 0.10 – 160 mm

- Achievable water cutting precisioN: ±0.10 mm (among other things, depending on the thickness and material type)

- Repeatability: ±0.05 mm

Advantages of the technology:

- No thermal effect of the warm water jet on the material

- Small cutting width

- Optimal use of the material

- Smoothness and sharpness of the edges

- Drilling holes

- Repeatability of the dimensions of workpieces

- No additional finishing work needs to be done as cutting leads to a finished product