TOUGHENED GLASS is 3-4 times more durable compared to regular glass of the same thickness. It also is more resistant to sudden temperature changes (200K). Due to its high impact and bending strenght, toughened glass is becoming a material often used in modern architecture. Its advantages have already been appreciated by architects, who implement more daring projects based on large glass areas, thanks to the use of toughened glass. It translates into improved living standard for users and reduced electricity consumption for interior lighting.

For examaple, bent glass manufactured by our company meets all the safety requirements and standards. In accordance with current regulations, each glass sheet is permanently labeled with the number of the standard and the name of the manufacturer. In the event of breakage, toughened glass breaks in a safe manner, i.e., it shatters into small pieces with blunt edges, therefore it reduces the consequences of possibe injury.

The manufacturing of toughened glass, such as bent glass, involves subjecting the final shaped glass sheet (dimensions, cut edges, possible holes, undercuts) to heat and rapid cooling. As a result of this process, compressive stress is generated on the glass surface, with counterbalanding tensile stress on the interior side.

Toughened glass can be used in:

- Whole-glass constructions/ very often as component panes of laminated glass

- Facades of buildings as insulated glass units, as well as single glazing

- Frameless storefronts

- Arcade galzing

- Traffic routes where intensive pedestrian traffic takes place

- Doors

- Fanlight

- Enclousers for balconies

- Railings

- Shower cabins

- Tabletops

- Shelves

- Furniture fronts

- As component of household appliances (refrigerators, stoves, ovens)

- Toughened glass is also used in the broader automotive industry, mostly as side and rear vehicle windows (cars, rail vehicles, agricultural tractors, construction machinery)

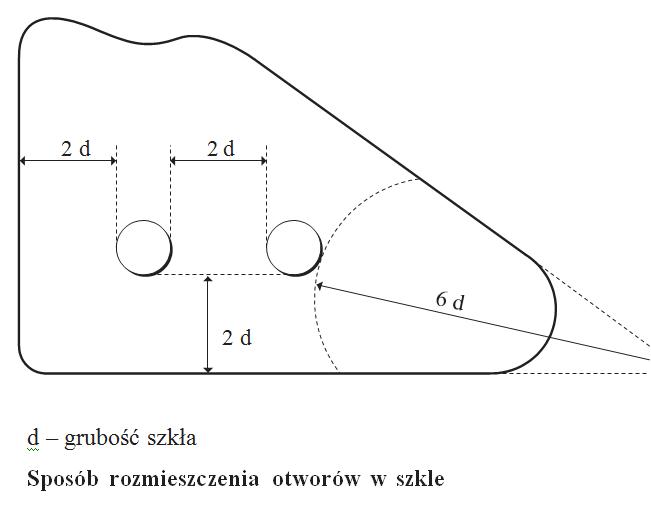

Notice:

- The diameter of the holes in the toughened glass must not be smaller than its thickness

- Holes must not be placed closer to the edge than 2x the thickness of the glass

- Distance between the edges of the holes must not be less than 2x the thickness of the glass

- Holes near the corners must be placed at a distance of not less than 6x the thickness of the glass.

Picture.

Our offer:

- Full range of glass processing before tempering, cutting straight and crooked linear shapes, blunting, chamfering, bevelling edges, drilling holes, cutting undercuts for hardware, bent glass, etc.

- Full set of glass elements for doors, partitions for all systems (DORMA, MORAD, GEZE, etc.)

- Toughened glass combined with laminated glass

- Insulated glass units made with toughened glass in all configurations

- Tempering of entrusted glass